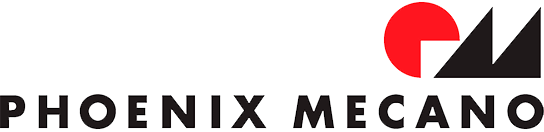

Linear Actuator LD1000C

The smart linear actuator

The LD1000C linear actuator is ideal for the digitalization and control of vehicles, machines and building sections. It is extraordinarily robust and strong: The thrust force is up to 10'000 N and the stroke length reaches up to 1'000 mm. The LD1000C is designed for rough outdoor applications. It functions with complete precision and reliability, even under extreme conditions.

Thanks to its integrated control unit, which can be adapted to your project, the external control electronics are, in many cases, no longer necessary.

The communicative linear actuator

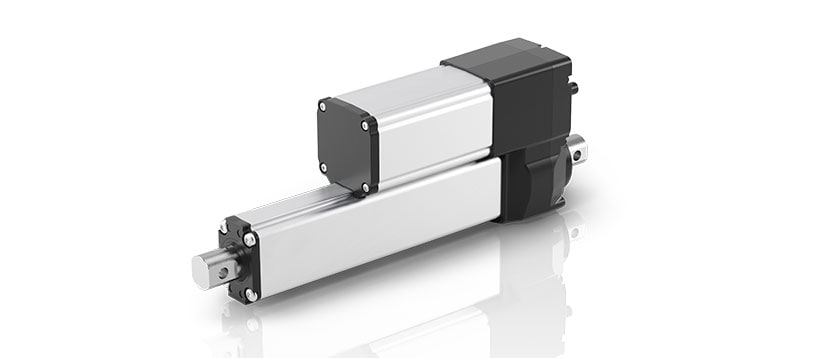

This model can be controlled via its CAN communication interface. The wide-range input voltage also allows the cylinder to be controlled directly by single-board computers such as the Raspberry Pi or controllers such as the Arduino. Elaborate adjustment circuits are no longer necessary. Digital control could not be made any simpler!

Updates can be imported directly via the CAN interface (a suitable PC with converter is required). Thus, complex connections are no longer necessary.

Customer benefits

Stroke length up to 1000 mm |

|

High pushing/pulling forces up to 10,000 N |

|

IP69K protection |

|

Built-in controller |

|

Robust housing |

|

Resistant to environmental influences |

|

Speed regulating |

|

Monitoring of current and temperature |

|

Synchronous operations with multiple drives |

Standard configurations

General Data |

|

|---|---|

Force |

max. 10.000N |

Speed |

max. 156mm/s |

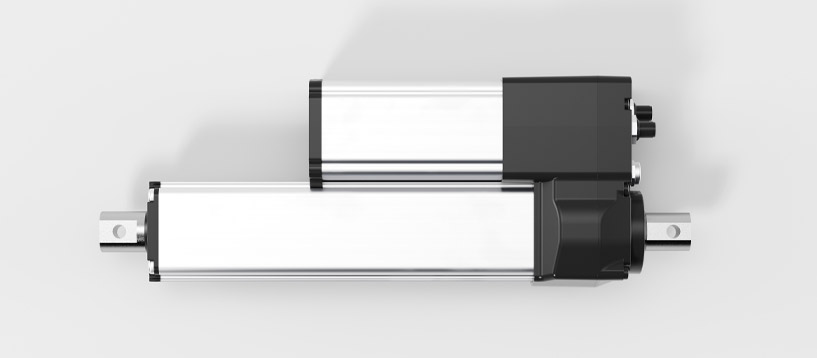

Stroke length |

min. 15mm - max. 1000mm |

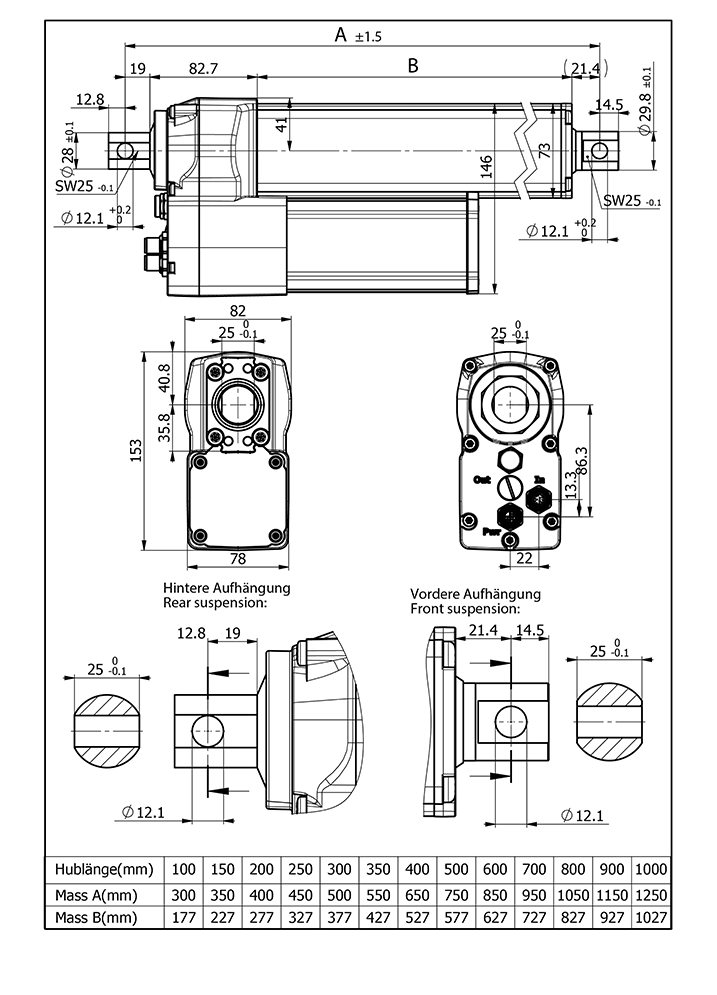

Installation dimension (A) |

smaller than stroke 400mm = stroke + 200mm greater or equal than stroke 400mm = stroke + 250mm |

NRLT Certificate |

yes, according UL 61800-5-1:2012/R:2021-02 and CSA C22.2 No. 274:2017 |

Duty cycle |

30% |

Position feedback |

yes |

Synchronous operation |

yes |

Supply voltage |

12VDC, 24VDC |

Intergrated limit switch |

yes |

End position signal |

yes |

Protection class |

IP69K (static) |

Self-locking |

up to nominal load |

Storage temperature |

-40°C bis +85°C |

Components |

|

Rod end |

Stainless steel, hole 12.1mm |

Housing end |

Stainless steel, hole 12.1mm |

Lift tube material |

Stainless steel |

Housing material |

Die-cast aluminum, anodized aluminum profile |

Housing colour |

similar to RAL 9005, black |

Connection |

Connector M12 |

Cable length |

3m, 5m, 10m |

Options |

|

| Suspensions individually selectable Special strokes adjustable ex works Special strokes adjustable by customer |

More data

Control / Regulation |

Programmable start/stop ramps Speed control Configurable speed Hand Switch PLC |

|---|---|

Position feedback |

End position feedback potential bound End position feedback potential-free Absolute position measuring system Analog position feedback Position feedback communication Communication interface |

Internal protection mechanism |

Power shutdown Temperature monitoring |

A variety of feedback options

Thanks to its integrated control unit and CAN interface, the LD1000C offers a variety of feedback options. The end position signals (digital outputs) can be used to control signal lamps, devices or relays. The analogue position feedback can be used for integrating into intelligent, complex control systems.

The absolute displacement measuring system opens up a wide range of control options and, in particular, enables the synchronous operation of up to six electric cylinders.

There is also high-resolution digital position feedback, which runs via the CAN interface. It records more than 4'000 steps per revolution, ensuring precision in the micrometre range when the position is queried via CAN.

An overview of the position feedback of the LD1000C:

- Final position feedback

- Absolute displacement measuring system

- Analogue position feedback. Configurable according to customer requirements

- Digital position feedback via the communication interface (CAN)

In addition to the position feedback, various parameters can be invoked via the CAN interface (operating voltage, motor current, position, status, etc.).

Versatile and customizable for perfect integrations

This linear drive is popular because of its great adaptability. You can order it precisely tailored to your needs.

- Movement profiles: We can program individual movement profiles into the integrated controller to precisely match your specifications.

- Speed: The movement speed can also be adjusted as required: either permanently programmed at the factory or controlled by you via software.

- Position feedback: We can configure the position feedback for you according to your needs. For example, you can specify certain voltage changes at freely defined positions.

- Stroke length: If the standard stroke lengths are not sufficient for you, we can program in your desired infinitely variable stroke length at the factory. Thanks to the CAN communication interface, it is also possible for you to set individual stroke lengths yourself.

- Hanging mechanisms, adapters, couplings: The hanging mechanism can be selected to fit your requirements. You can also define your own specifications (e.g. with regard to the bore holes). We deliver the linear drive exactly according to your specifications.

- Housing: Customized paints, special colours and special installation dimensions – everything is possible.

- Control: In addition to the CAN communication interface, the electric cylinder can also be controlled with a handset or via digital signals.

- Operating voltage: Here, too, you have several versions to choose from – ranging from 12 VDC to 48 VDC.

- Safety: An overload clutch and manual emergency actuation feature are available optionally.

- Cable length and plug: The cable length and connections / plugs can be customized on request.

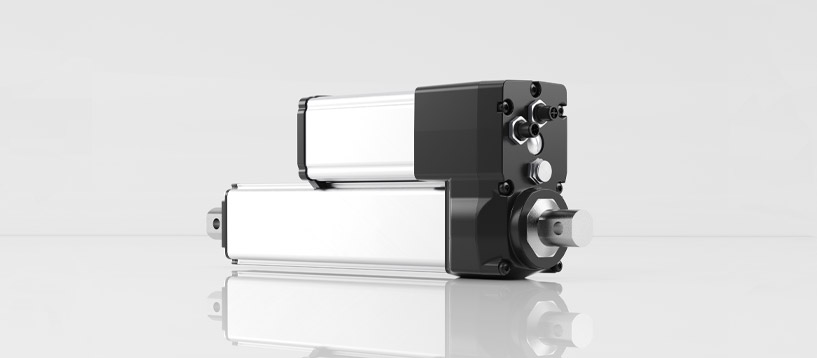

High quality and resistant

The LD1000C has a robust housing made of die-cast aluminium with a stable casing made of anodized aluminium profile and a lift pipe made of stainless steel. Inside, there is a maintenance-free DC motor that features enormous reliability and longevity. The housing and hanging mechanism are manufactured with the greatest care and precision.

Thanks to its high protection class of IP69k (static), the housing can withstand a jet from a high-pressure steam cleaner without any problems.

Even under extreme environmental conditions, the linear drive is reliable and trouble-free. It can tolerate ambient temperatures of -20 to 65 degrees Celsius and is insensitive to UV radiation from the sun.

This linear drive is also popular in the offshore sector (e.g. for ocean-going yachts or cruise ships). Years of operation while in contact with seawater and salt spray do not affect its reliable functionality. Likewise, the violent vibrations of off-highway machines cannot harm it.

Forward-compatible investment

We can save your delivered configuration of the LD1000C for as long as you wish. This way, you can order more with exactly the same configuration from us many years later. When using the LD1000C, you avoid the need for complicated adjustments to your machines later on and expensive repetitions of acceptance tests.

Typical areas of use

The LD1000C is often used in outdoor applications: for agricultural machinery, off-highway vehicles, municipal machinery and even in the offshore sector. In other words, it can be used wherever the linear drive must function precisely and reliably under harsh environmental conditions. Here are some typical examples of LD1000C usage:

Agricultural machinery:

- Adjusting the ear lifters in combine harvesters

- Configuring round balers

Mobile and off-highway:

- Used instead of hydraulic components in construction machinery

- Folding up of traffic signal equipment on municipal vehicles

- Height adjustment of conveyor belts, for example airport baggage belts for loading aircraft

Offshore and marine technology:

- Tilting a GPS antenna

- Controlling bathing platforms

- Opening and closing of dinghy/tender garages

Industrial and logistics

- Controlling loading ramps

- Lifting and lowering functions for transport racks

- Lowering of goods carriers in industrial trucks